Steam boilers play a crucial role in many industrial sectors. Whether they are used for power generation, heating, or technological processes, their reliability has a direct impact on the efficiency of the entire installation.

However, in addition to scheduled and unscheduled maintenance, there are times when a boiler replacement becomes necessary in order to meet changing requirements or improve operational efficiency.

In the article below, we will discuss the differences between these two types of maintenance and explain why their proper execution is so important.

Planned Overhaul of a Steam Boiler

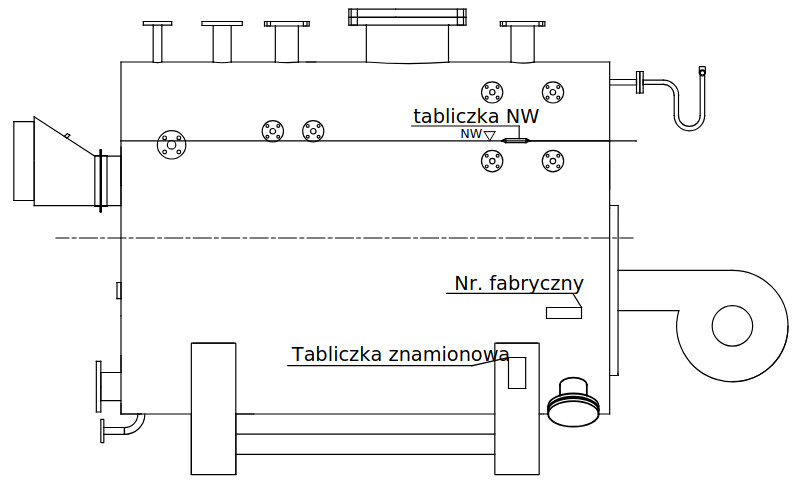

A planned overhaul of a steam boiler is a process carried out according to a pre-arranged schedule. It includes inspections, maintenance and replacement of worn components before their condition begins to threaten the device’s safety or performance. Among the most important activities performed during a planned overhaul are cleaning the heat-exchange surfaces, checking and refurbishing valves, assessing the condition of piping and tanks, and replacing seals and other consumable elements.

Planned overhauls help avoid unexpected downtime and extend the boiler’s lifespan. In addition, they allow the facility to schedule service work at an optimal time, thus minimizing production disruptions.

Unplanned Overhaul of a Steam Boiler

Despite regular inspections and maintenance, there may arise an urgent need for overhaul when a sudden drop in performance occurs or serious malfunctions are detected in the device. In such situations it is essential to quickly identify the problem and implement appropriate corrective actions. Most commonly, an unplanned overhaul involves repair or replacement of structural components, removal of control-system faults, and refurbishment of heat-exchange elements. An unplanned overhaul demands flexibility and fast response, which is why it is wise to work with experienced experts who have the proper technical background and equipment.

Replacement of the Steam Boiler

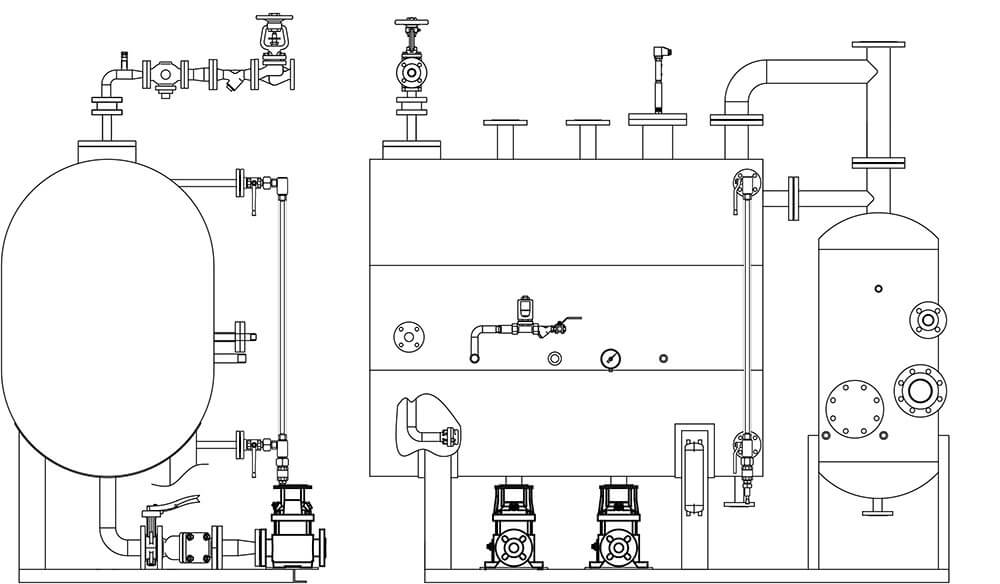

In some cases, especially when repair costs exceed the value of the device or its parameters no longer meet current needs, the best solution may be replacing the steam boiler with a new one. The replacement process includes several key stages: assessment of the existing boiler’s technical condition, selection of a new device with appropriate parameters, preparing the infrastructure for installation, as well as mounting and commissioning the new boiler. Condensing out the old boiler and installing the new one can offer multiple benefits, such as improved energy efficiency, reduced operating costs and better alignment with modern production requirements. It is crucial that this process is carried out in accordance with safety norms and in cooperation with experienced professionals.

Why Maintenance and Replacement of Steam Boilers Are Worthwhile

Regular maintenance, scheduling planned overhauls and a properly conducted boiler replacement are key to ensuring long-lasting and reliable boiler operation. Despite the best preparation, the possibility of an unplanned overhaul always remains, and in some cases replacing the unit with a new one may prove the most effective option. That is why it is worth partnering with companies that offer comprehensive support in boiler servicing and replacement. This approach allows you to minimize the risk of unexpected downtime, improve energy efficiency and ensure continuity of your plant’s production processes.