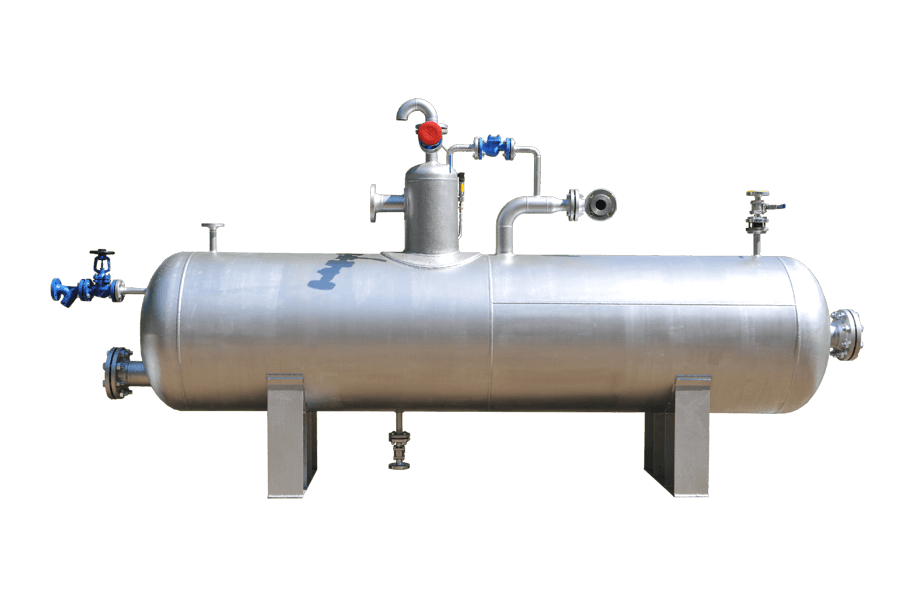

Ruths steam accumulators are key elements of steam systems in the food, textile and construction industries. The Ruths accumulator offered by us is carefully manufactured and meets high quality requirements. The Ruths tank is adapted to the user’s specifications, guaranteeing high quality and reliability. Each steam accumulator is designed in accordance with the requirements of the installation, which ensures optimal use of thermal energy and stability of the system.

Ruths’ reservoir – types

In steam systems and the energy sector, steam accumulators play a key role in optimizing thermal energy consumption. These specialized pressure devices come in two basic versions: horizontal and vertical. Each of them has unique properties that make them suitable for use in various industries.

Ruths Steam Tank Horizontal

The Ruths Horizontal Tank is a device designed for systems requiring uniform storage and distribution of heat. Its design allows for minimizing heat energy losses, which directly translates into increased efficiency of the entire system. It provides constant access to steam, which is crucial for the uninterrupted operation of industrial processes, and at the same time allows for savings in operation by reducing operating costs, making it an irreplaceable element of modern steam installations. This solution is particularly valued in industry, where the stability of steam supply directly affects the quality and efficiency of production.

Zasobnik Pary Ruths’a pionowy

The Ruths vertical steam tank is distinguished by its compact design, which makes it an ideal solution for plants with limited space. Its construction allows for space saving without losing efficiency. Additionally, it stabilizes the system, ensuring even steam supply, which is crucial for the uninterrupted operation of the installation. Thanks to the optimization of technological processes, it allows for precise control of parameters, which translates into greater efficiency and reliability in industrial applications. The most important advantages of the Ruths vertical steam tanks are space saving, system stabilization, optimization of technological processes.

Zbiorniki typu Ruths Podlegają zgłoszeniu do UDT.